Costanza - Masonry Kitchen

Building

A masonry kitchen built in a carpenter's shop can offer the beauty of a traditional kitchen, with the unique charm of stone masonry, and the functionality of a modern kitchen, that can be easily disassembled.

In a masonry kitchen you experience the advantage of a modern kitchen and the beauty of a traditional one.

The construction of a masonry kitchen starts from the wall unit, then you go on with the base cabinet that must be assembled with walls that vary from 80-90 and 100 mm.

This measures are essential to maintain the same appearance and they change accordingly to the wall conditions, the wall can if they are between two base cabinets or if the wall is protruding.

In this last case, the base cabinet on the back should have a support to be accurately manufactured.

After the base cabinets, we must think about the top, because it has to be fastened to the base cabinets and to the walls;

dobbiamo solo lasciare che le mattonelle a muro siano indipendenti, in modo che all'occorrenza, la cucina possa essere smontata.

Piu' tardi si posano le piastrelle, che possono essere fatte di vari materiali, come il gres; ma la piu' bella di tutti è la pietra naturale.

Si utilizzano colle speciali per legno e pietra e colla standard in polvere per pietra e muro.

la pietra viene poi applicata e gli spazi puliti prima con lana di acciaio, perchè le pietre calcaree rilasciano acqua nelle successive 12 ore, consiglio di pulirle con i polpasrtrelli per un risultato naturale.

Successivamente, le mattonelle devono essere trattate con vernici impermeabili, che non alterano il colore della pietra: più tardi, utilizzo una cera per far durare più a lungo la pietra e renderla impermeabile.

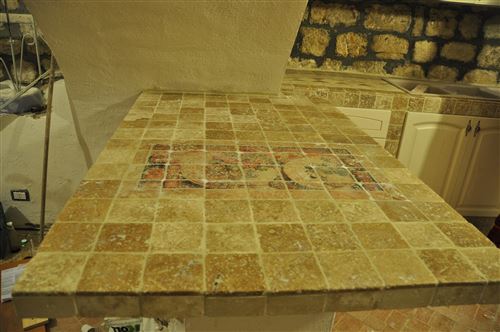

Le foto in basso mostrano alcuni tipi di lavorazioni complesse e particolari.

One of the most complex manufacturing is the stone cutting because, sometimes, stones have uneven shapes. Cutting is made with a water machine with a diamond-blade. After the cutting, stones must be smoothed with sandpaper to remove the diamond-blade signs.

This image shows the difficulty of the top manufacturing, if you have an uneven wall; you can notice that the stones of the perimetral countertop need to be shaped, because they do not have linear surfaces.

In this photo you can see details about the laying of tiles on vertical walls... the depth between stone and stone is obviously not accidental, but it is calculated before the work starts, in order to have uniform spaces on the whole surface.